My Portfolio

A selection of my projects

Blackjack

An Arduino-based Blackjack game with speakers and addressable LEDs

PCB Design

Soldering

Fusion

C++

3D Printing

S.U.L. - Secure Under-Bed Lighting

A under-bed lighting solution with removalable magnetic lights and key switch

PCB Design

Soldering

Fusion

C++

3D Printing

Blood Pressure Monitor Reverse Engineering

Reverse Engineering of a Blood Pressure Monitor

SOLIDWORKS

SOLIDWORKS Visualize

Let's Connect

Looking to contant me?

The best way to reach me is by email.

You can also find me on social media:

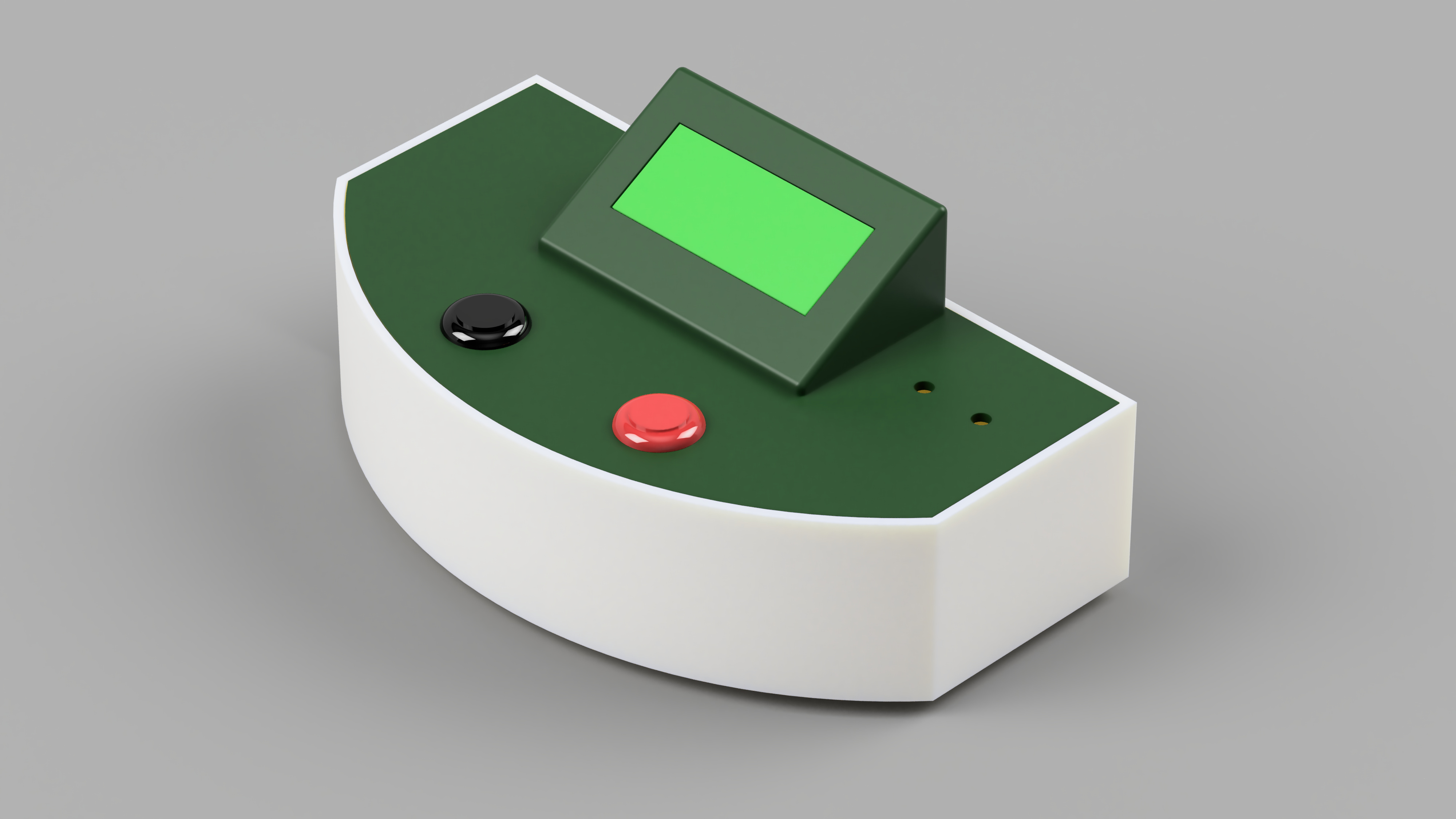

Blackjack

An Arduino based Blackjack game with speakers and addressable LEDs

About this project

Project Overview: This project served as my Engineering Design Division (EDD) capstone, where I led the modification of an Arduino-based text adventure game. My key technical contributions include:

-

Hardware Engineering: Designed the program's first-ever custom PCB using KiCad and created a blackjack-style enclosure, modeled in Fusion 360 and 3D printed.

-

Circuit Design: Engineered a custom Arduino Shield featuring an RC low-pass filter with a minimum cutoff frequency of 159 Hz to smooth PWM square waves and eliminate harsh harmonic noise. The design includes optimized power distribution to drive the LEDs, speaker, and screen while maintaining temperatures within safe limits.

-

Software Development: Led a complete overhaul of the source code in C++, rewriting the game engine from the ground up using a state machine. Integrated the FastLED library for LED lighting effects and music with gameplay, while retaining only the core button input logic.

The biggest challenge was learning to use KiCad to design an effective board layout without prior experience. I specifically focused on isolating the audio signal from the LED power traces to minimize noise. The budget was also a major constraint, given the extensive modifications required, including the arcade-style buttons, speaker, amplifier, larger screen, and LED strip.

Technologies Used

- Fusion 360

- KiCad PCB

- 3D Printing

- C++

- Soldering

- Arduino

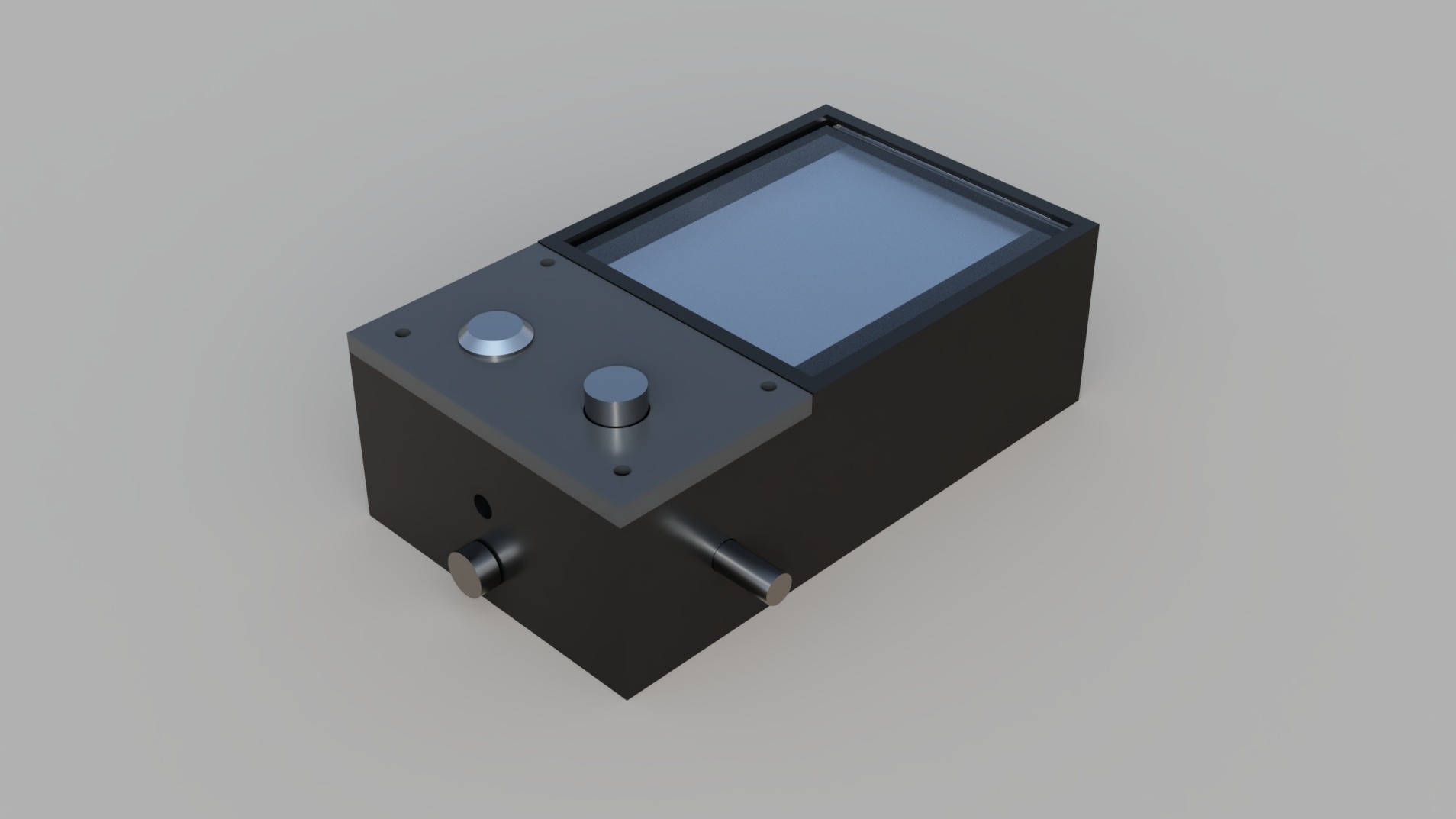

S.U.L. - Secure Under-Bed Lighting

A under-bed lighting solution with removable magnetic lights and key switch

About this project

Project Overview: This independent engineering project focused on designing and fabricating a custom lighting system for my dorm's lofted bed. I completed the PCB design, component soldering, enclosure fabrication, and final installation.

-

Hardware Engineering: The enclosure was modeled in CAD and 3D printed; I added a laser-cut acrylic window and heat-set inserts to create a housing that is both serviceable and durable. I also created a simple magnetic mounting system to ensure the bed would be undamaged by the LED strip. The mounting system also allows the strip to be reused.

-

Circuit Design: I adapted a multi-purpose PCB (I originally designed in KiCad for a Blackjack project) by adding a rotary encoder and switches. The power distribution was already robust and capable of driving the 345 LEDs. The system is powered by a 5A 5V barrel power supply.

-

Software Development: I developed firmware utilizing the FastLED library to manage lighting effects. Implemented logic where a "long press" on the rotary encoder shifts the system into a color temperature control mode, allowing for adjustment between warm and cool lighting temperatures.

Challenges & Constraints: The primary design constraints were physical footprint and cable management; the system needed to be easily accessible and mounted non-destructively while keeping wires hidden. A major technical hurdle was solving the voltage drop across the extended LED strip, which I successfully solved through wiring modifications.

Technologies Used

PCB Design

Soldering

Fusion

C++

3D Printing

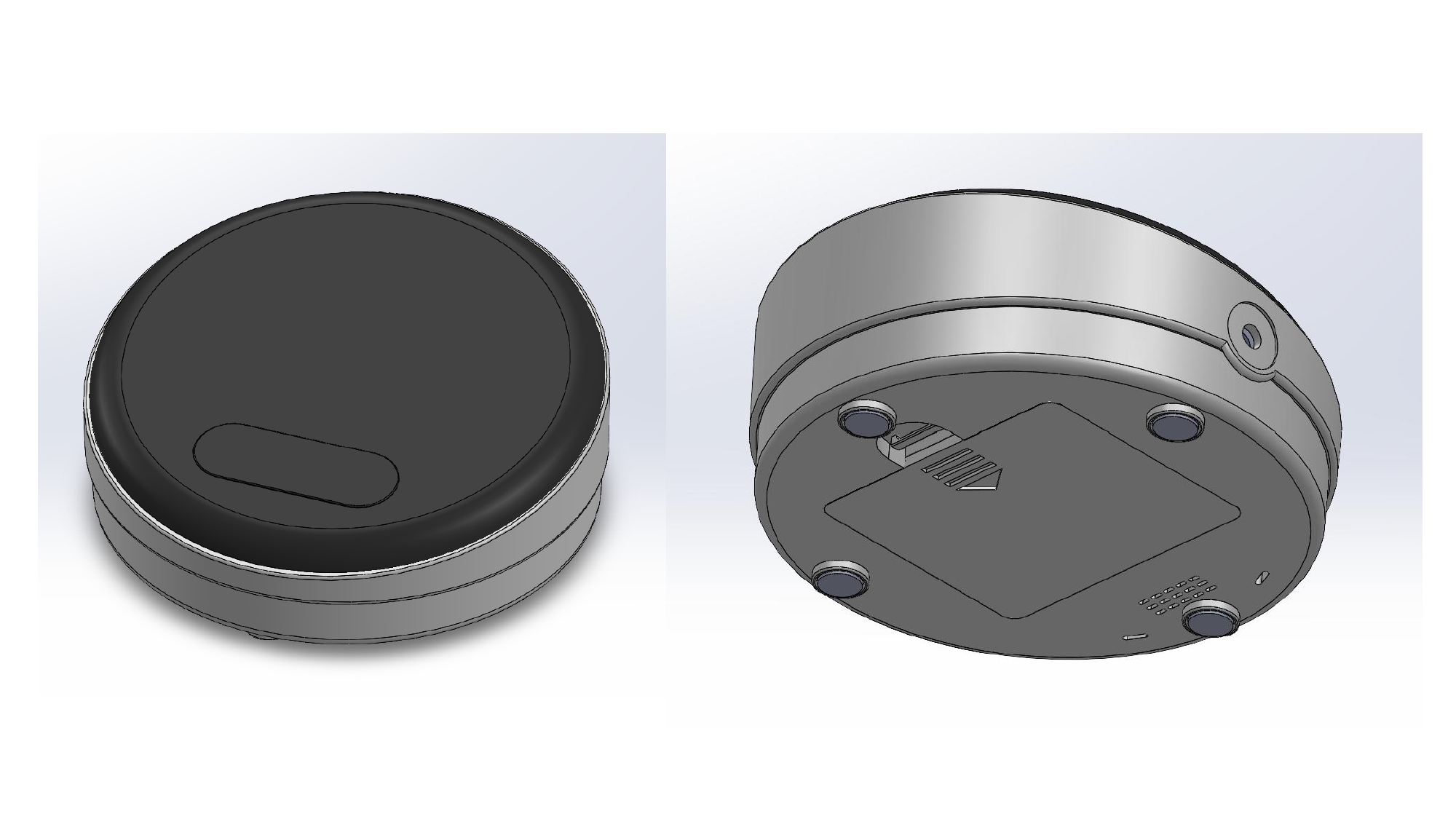

Reverse Engineering

Analysis and CAD reconstruction of a Blood Pressure Monitor.

About this project

Project Overview: Collaborated with a team of engineering students to perform a complete reverse engineering analysis of a commercial blood pressure monitor. The project included disassembly, component modeling, functional analysis, and identifying design improvements.

-

CAD Modeling: Measured and modeled 12 distinct components using SOLIDWORKS.

-

Simulation & Animation: Utilized SOLIDWORKS Visualize to create a 3D animation demonstrating the pressure measurement system.

-

Technical Report: Co-authored a 44-page engineering report detailing the system’s operation. The report concluded with a set of proposed design modifications to enhance the device.

Technologies Used

SOLIDWORKS

SOLIDWORKS Visualize

Reverse Engineering Report

Loading PDF and generating previews...